Engineered Lifting and Positioning Solutions for Intensive Use and Automation

Tesis Engineering has extensive experience in the design and manufacture of custom engineered systems in the field of industrial handling: we can offer lifting and positioning solutions purposely designed to be integrated into automated production lines or interfaced with other machines.

Our lifting and handling systems are designed to comply with the customer's technical specification, we focus on the overall result necessary to make our solutions perfectly integrated into the final complex.

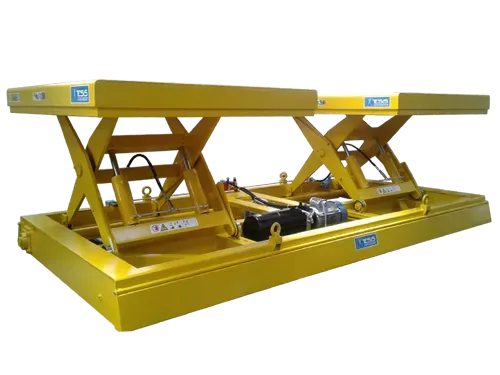

Heavy-duty lift table with shaped platform, fixed bevelled lateral riser and motorized retractable stopping chocks integrated into the platform top.

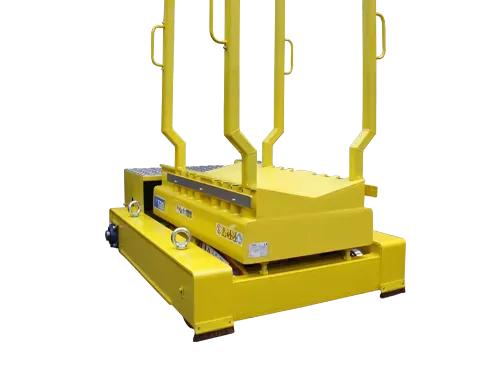

Scissor lift with motorized cradle counter-platform. Counter-platform options: sliding, tilting, rotating/swinging or lateral extension movements.

Heavy duty scissor lift equipped with flush mount motorized turntable and motorized retractable stopping chocks integrated into the platform top.

Rail-guided self-propelled scissor lift with V-cradle shaped platform top. Motorized holding paddles with manual distance adjustment crank handle.

Heavy-duty lift tables and engineered handling systems for process automation

Our line of heavy-duty platform lifts and custom-designed material handling equipment, covers the largest and most demanding industrial applications.

Tesis Engineering's engineered solutions are employed in the broadest industrial process automation field, including:

- Metalworking: applications for winding and unwinding, cutting, bending, flattening laser cutting machines, pipe production lines, press feeding.

- Bottling and packaging: applications for craters and de-aters machines, packaging lines, palletization.

- Paper and cardboard processing: applications for tending gravure printing lines, printing lines for laminates, impregnation, coupling and lamination lines, cardboard production.

- Automotive: applications for vehicle production lines, painting, testing and prototyping.

- Glass processing: applications for tempering and lamination furnaces.

- Woodworking: applications for presses and panel production machines.

- Production of electric cables and metal wires: applications for winders and unwinders, submarine cable testing tanks.

- AGV and shuttles for processing lines: applications for AGV and shuttles

- Molding of plastic materials: applications for mold replacement, press tending,

- Sterilizing: applications for autoclave

- Applications for machines and processing lines in general, of any production sector

Handling, lifting and transfer equipment for Coils, Rolls and Reels

Tesis Engineering offers a variety of specific solutions for the handling, loading / unloading and positioning of coils (sheet metal, etc.), rolls (fabrics, plastic nets, etc.) and reels (paper, plastic films, cables, etc.) of different materials, rigid, flexible, light or heavy.

Tesis Engineering's roll handling lift tables are available in the fixed and self-propelled version. To meet the specific requirements of the application, they can be configured with a variety of options: cradle-shaped platform, retractable coil chock devices recessed in the platform top, ejectors, support systems to handle rolls of various sizes, roller conveyor, centering devices, turning, shifting or tilting platform, etc.

Loading-unloading and handling systems for Bars, Plates and Sheets

Tesis Engineering's pallet changing systems help to improve production efficiency by reducing the time required for loading/unloading and pallet switching operations (laser cutting lines, sheet metal palletization, paper, PVC, laminate, etc.)

Pallet changers units using pantograph lifters, based on the specific needs of the production process involved, can be made both for loading / unloading from below in the floor version, and for loading / unloading from above in the suspended version or in combination of the two.