Triple Scissor Lift Tables

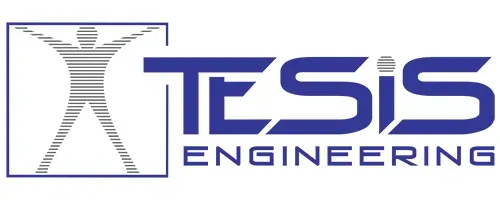

h = minimum height, C = vertical travel, AxB = platform dimensions (see dimensional scheme in Data and specifications sheet), * = available only with external power unit

| Serie XH | 600 kg | 1.000 kg | 2.000 kg | 3.000 kg |

|---|---|---|---|---|

| A x B (mm) | h / C (mm) | h / C (mm) | h / C (mm) | h / C (mm) |

| 650 x 400 | 430* / 1000 | 450* / 1000 | - | - |

| 650 x 500 | 430* / 1000 | 450* / 1000 | - | - |

| 650 x 600 | 430* / 1000 | 450* / 1000 | - | - |

| 850 x 500 | 480* / 1350 | 500* / 1350 | - | - |

| 850 x 600 | 480* / 1350 | 500* / 1350 | - | - |

| 850 x 700 | 480* / 1350 | 500* / 1350 | - | - |

| 1000 x 600 | 500* / 1800 | 510* / 1800 | - | - |

| 1000 x 800 | 500* / 1800 | 510* / 1800 | 540* / 1800 | - |

| 1000 x 1000 | 500* / 1800 | 510* / 1800 | 540* / 1800 | - |

| 1250 x 600 | 570* / 2400 | 580* / 2400 | - | - |

| 1250 x 800 | 570* / 2400 | 580* / 2400 | 610* / 2400 | 650* / 2310 |

| 1250 x 1000 | 570* / 2400 | 580* / 2400 | 610* / 2400 | 650* / 2310 |

| 1250 x 1200 | 570 / 2400 | 580 / 2400 | 610 / 2400 | 650 / 2310 |

| 1550 x 600 | 590 / 3150 | 600 / 3150 | - | - |

| 1550 x 800 | 590 / 3150 | 600 / 3150 | 630 / 3150 | |

| 1550 x 1000 | 590 / 3150 | 600 / 3150 | 630 / 3150 | 670 / 3075 |

| 1550 x 1200 | 590 / 3150 | 600 / 3150 | 630 / 3150 | 670 / 3075 |

| 1550 x 1500 | 590 / 3150 | 600 / 3150 | 630 / 3150 | 670 / 3075 |

| 2000 x 1000 | 730 / 4050 | 740 / 4050 | 780 / 4050 | 830 / 3900 |

| 2000 x 1500 | 730 / 4050 | 740 / 4050 | 780 / 4050 | 830 / 3900 |

| 2000 x 2000 | 730 / 4050 | 740 / 4050 | 780 / 4050 | 830 / 3900 |

| 2500 x 1000 | 760 / 5040 | 770 / 5040 | 810 / 5040 | 920 / 5000 |

| 2500 x 1500 | 760 / 5040 | 770 / 5040 | 810 / 5040 | 920 / 5000 |

| 2500 x 2000 | 760 / 5040 | 770 / 5040 | 810 / 5040 | 920 / 5000 |

| 3000 x 1000 | 960 / 6180 | 960 / 6180 | 1000 / 6180 | 1070 / 6040 |

| 3000 x 1500 | 960 / 6180 | 960 / 6180 | 1000 / 6180 | 1070 / 6040 |

| 3000 x 2000 | 960 / 6180 | 960 / 6180 | 1000 / 6180 | 1070 / 6040 |

Data and characteristics are indicative and non-binding and may be subject to change without notice

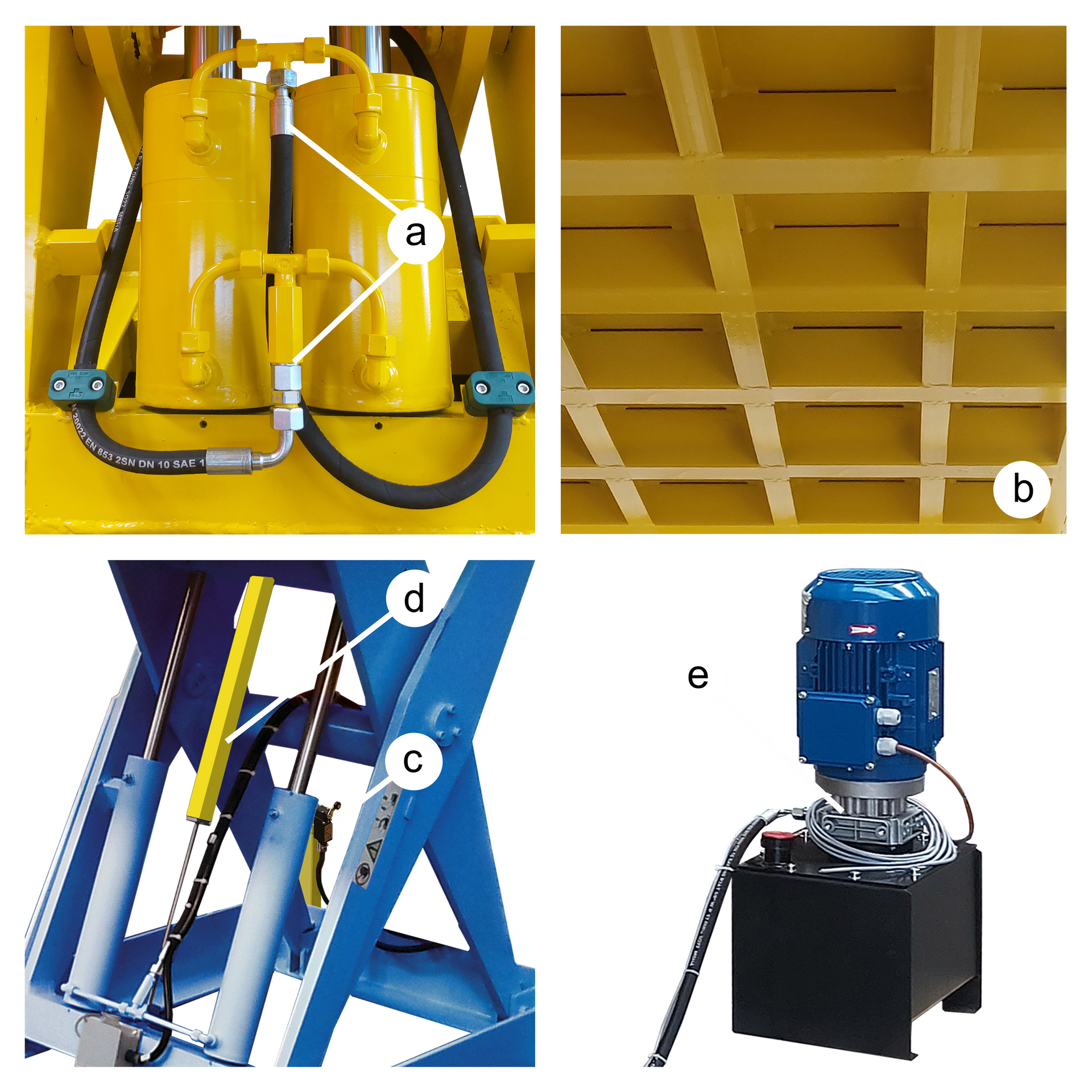

XT Series Lift Tables - ACCESSORIES

- Checker or striated non-slip platform surface; covering tops in stainless steel, aluminum or rubber

- Access or inspection hatch in platform top

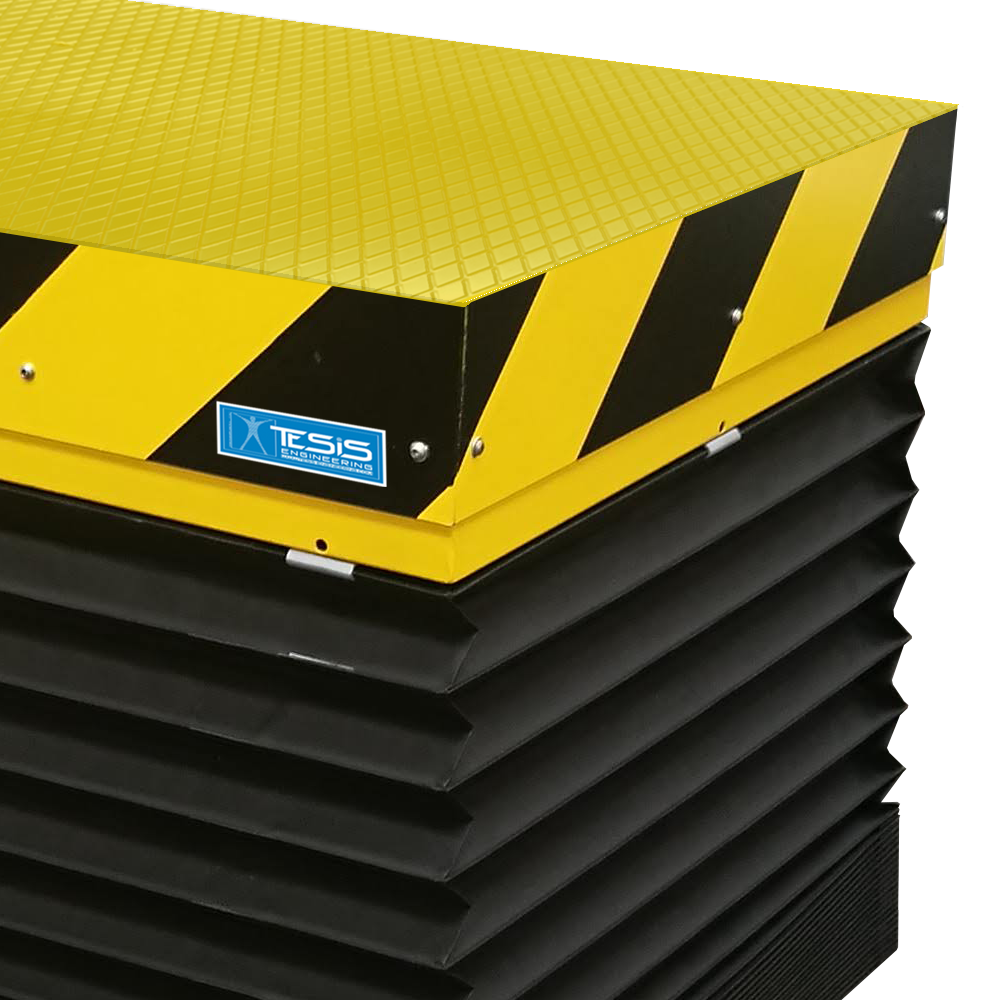

- Bellow skirting under the platform

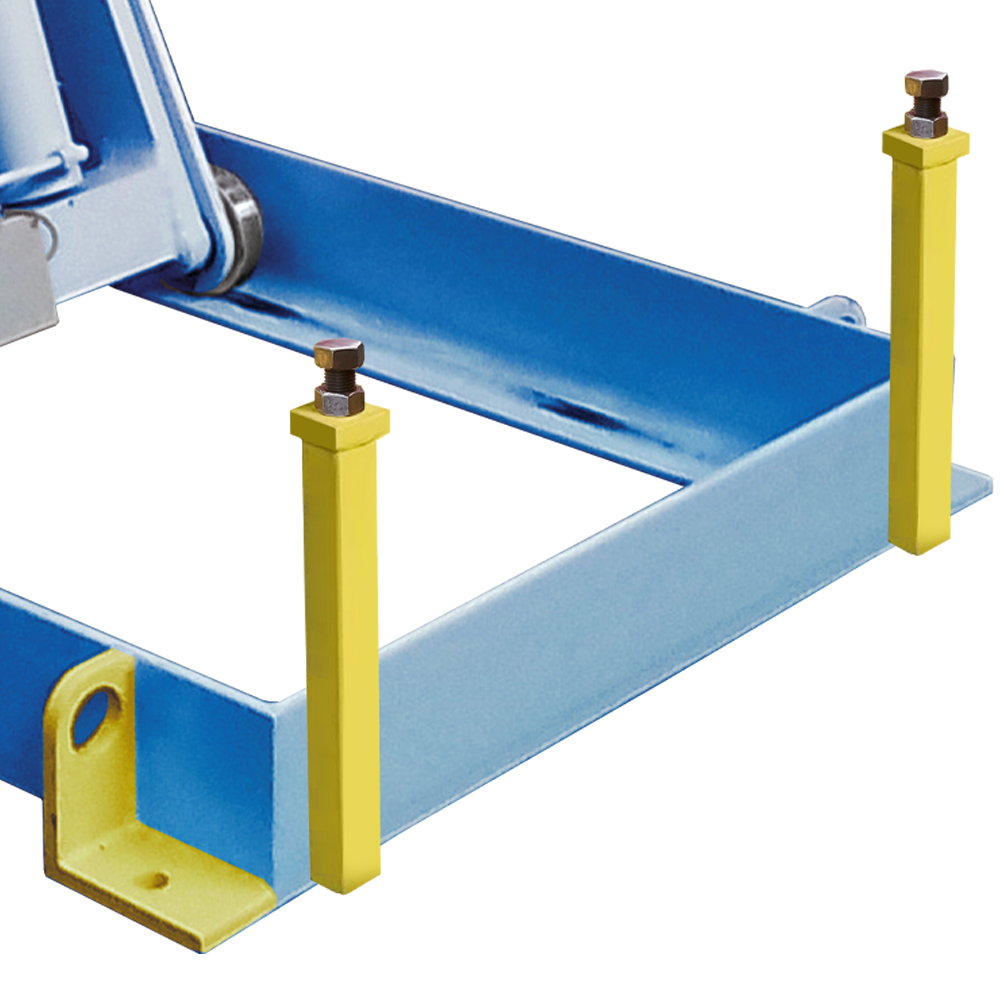

- Base supporting posts for closed platform

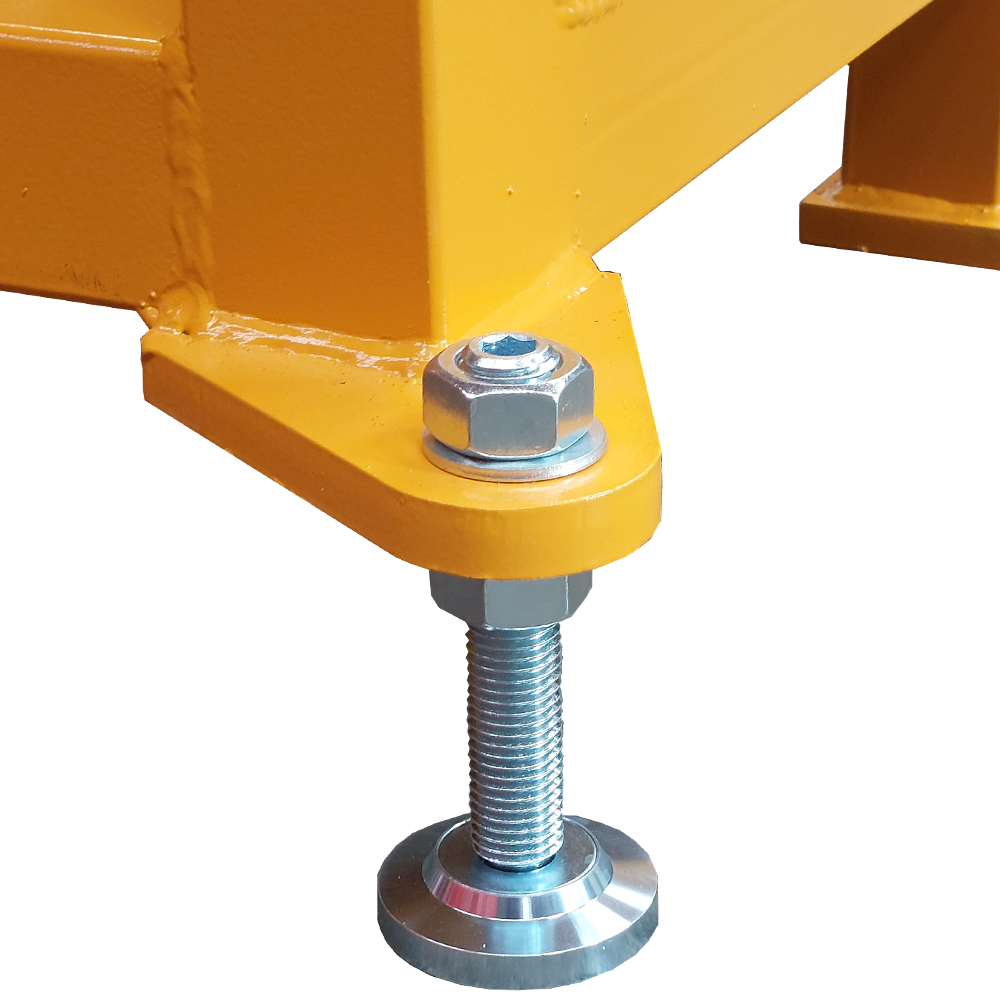

- Level adjusting posts on reinforced base

- Floor fixing plates or angles

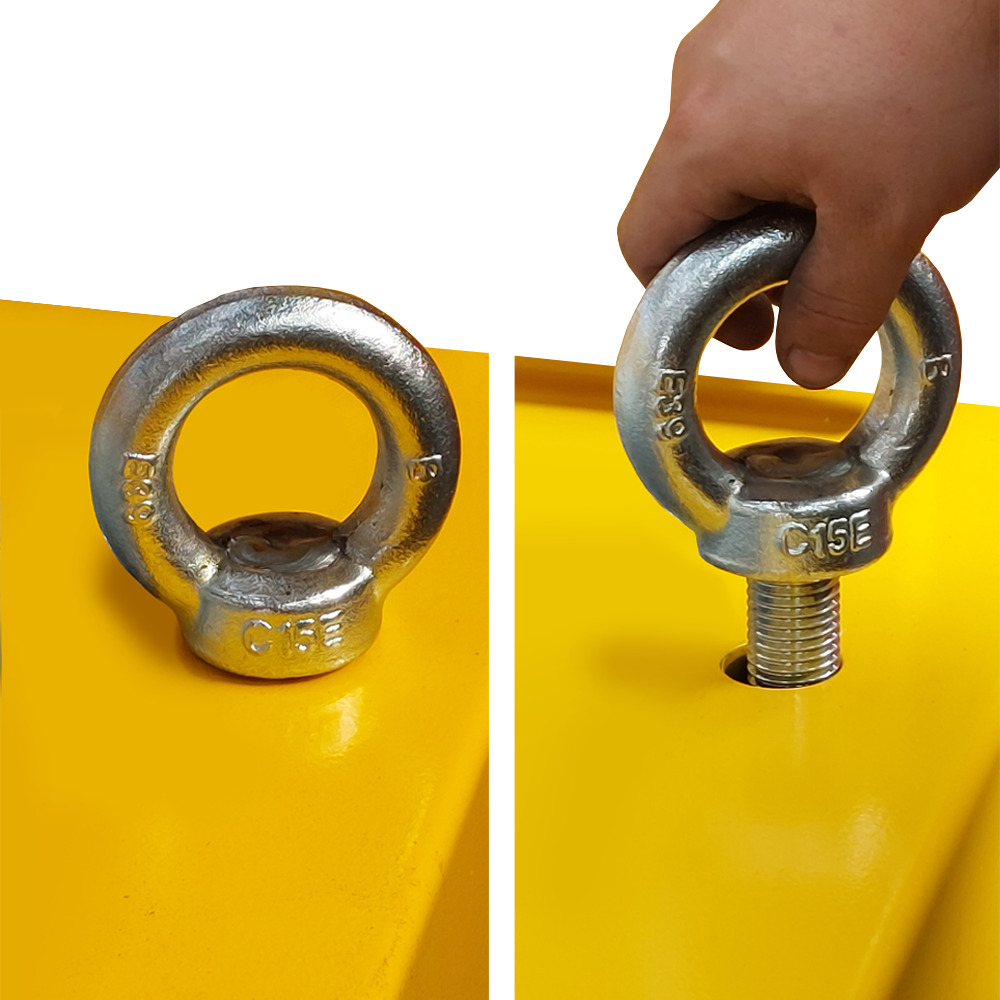

- Forkable base, eyebolts or brackets for handling

- Wheeled base, stabilizers, push bar or handle

- Fixed or hinged side edges, approach ramps

- Fixed or removable guard-rails, access gates

- Push-button panel with enabling key, wall-mounted push-button panel, foot controls, floor stand for push-button panel

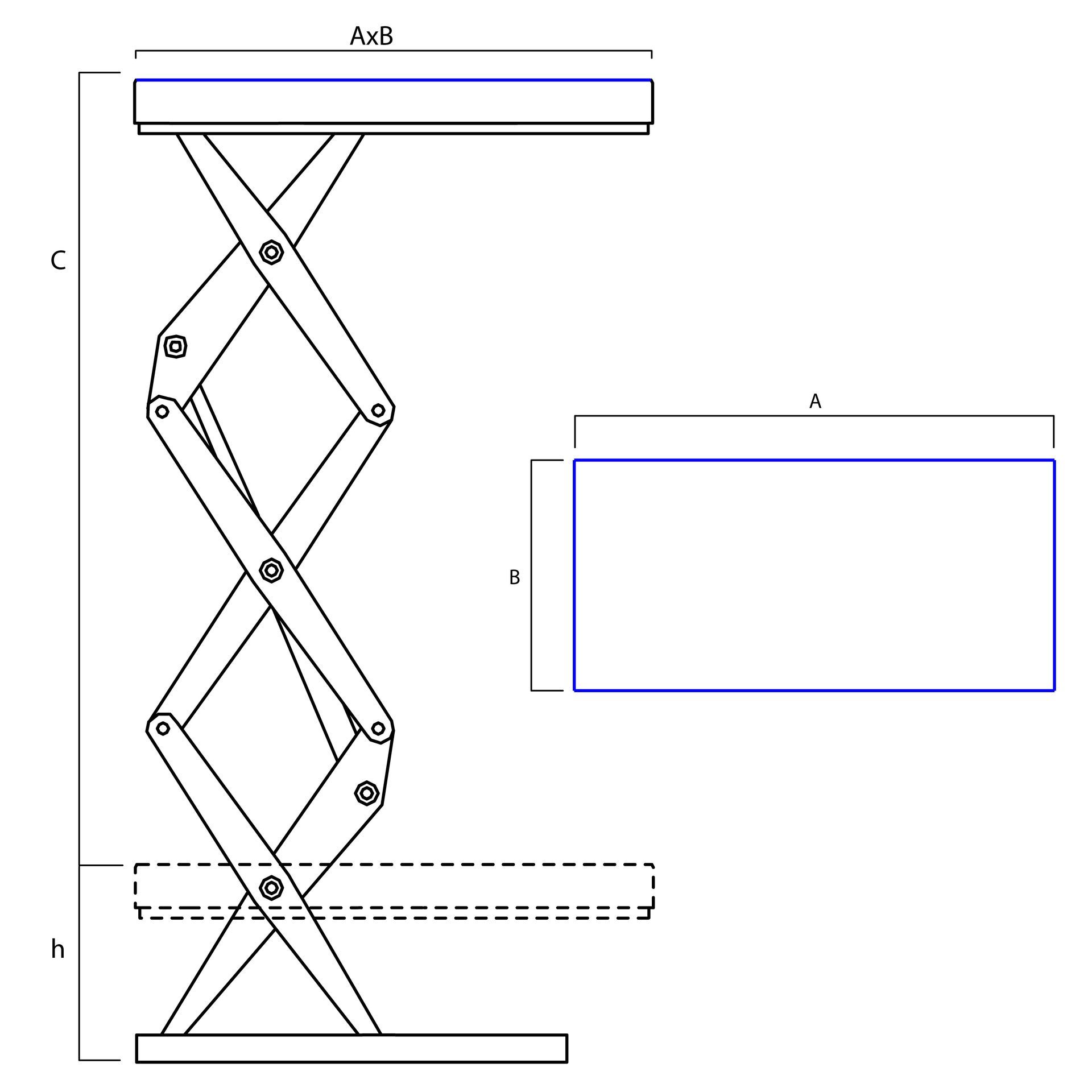

- Anti-swing side gliding pads or rollers and guides

- Special packaging, wood boxes and crates