Engineered Industrial Handling Solutions and Special Projects

When it comes to special requirements, custom engineered machines or a specially designed product, Tesis Engineering can provide engineering and manufacturing for unique projects, targeting very different applications. By combining the expertise of our engineering and manufacturing teams, we are able to translate our customers' needs into a viable product solution.

Check out below for some examples of what we can do.

Handling Line for Rolls

Handling line for packing machine of conveyor-belt rolls:

- Self-propelled shuttles with tilting powered roller conveyor

- Fixed powered roller conveyors

- Tilting lift tables

- Final accumulation station with powered chain conveyor and gravity rollers (for up to 4 rolls of max dimensions)

Load: Rolls of conveyor-belt diam. min/max 400 / 1.200 x width. min/max 500 / 3.400 mm, max weight 3.500 kg.

Self-propelled Shuttle for Rolls

Self-propelled shuttle for loading/unloading rolls of plastic film from slitter / rewinder machine:

- Rail-guided powered traverse

- Gravity flat roller conveyor with blocking device

- Anti-collision sensitive edges on both travel directions

- Slow down / stop devices on both travel directions

Load: 1 mother roll of plastic film, diam. max 1,200 x width. max 2.050 mm, or up to 5 slitted rolls diam. min/max 300 / 1.200 x width. min/max 80/650mm, max. 4,000 kgs.

Vertical Accumulation System for Rolls

Vertical accumulation system for rolls of fabric, with lifting shuttle and multi-level accumulation storage:

- Powered rail-guided shuttle moving vertically along the central lane, tiltable both to the right and left for picking / depositing rolls from/to lateral storage shelves

- Powered retractable roll holding devices on both sides of the shuttle

- Shuttle equipped with belt conveyor for transferring rolls from incoming lines on several levels and towards an outgoing line.

- Lateral multilevel storages with powered tilting shelves

Load: Rolls of fabric, diam. min/max 60 / 550 x width. min/max 1.200 / 2.000 mm, max. 80 kg.

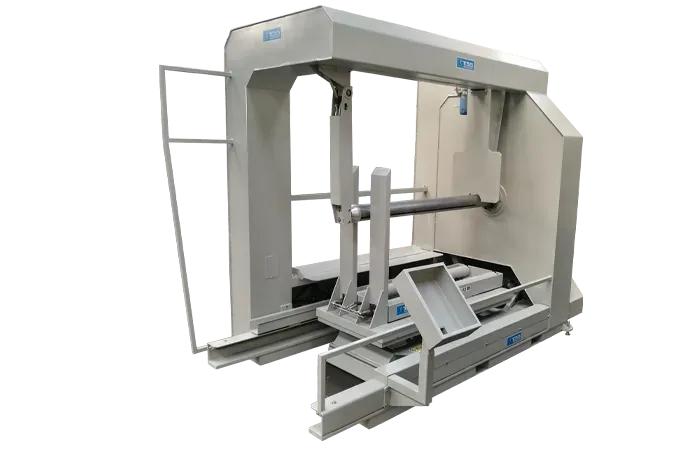

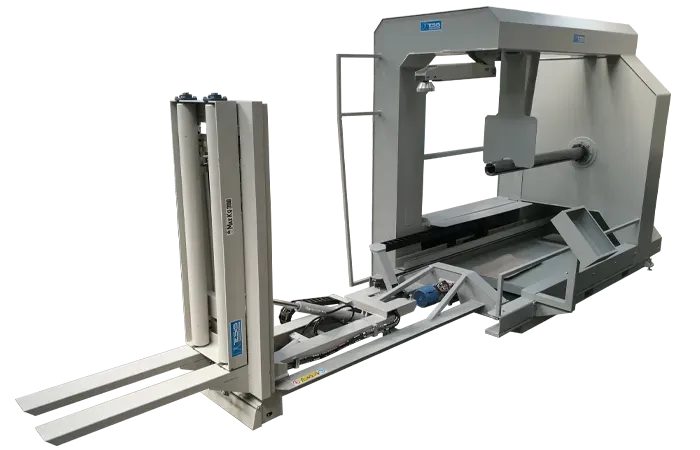

Winder with Extractor / Palletizer for Rolls

Net roll winder with extraction system and deposit on pallet:

- Winding machine arranged for quick coupling of different types of shafts, equipped with retractable shaft stabilization device

- Roll ejection system by pusher

- Rail-guided self-propelled roll's extraction lift table, equipped with powered packaging rollers, weighing load cells and tilt table with forks for palletizing operations

Load: Rolls of polyethylene net, with or without core, diam. min/max 400 / 1200 x width. max. 1200 mm., max weight 300 kg.

Electric Three-Wheeler Vehicle - TUK TUK

Engineering of a new three-wheeler electric vehicle (Tuk Tuk) intended for use in South-Est Asian countries for transporting people or goods:

- Vehicle Engineering

- Vehicle Design

- Prototyping and testing

Features: Class L5e max 45 km/h - 1 driver + max 3 passengers - full electric power supply - standard, rapid or battery swap charging system.

Vehicle Transformation with Electric Retrofitting

Electric retrofitting on a used Nissan Patrol Y61 vehicle purposely modified and customized for participation in non-competitive contest in Africa (Elephant Charge - Zambia)

- Engineering, manufacturing and installation of the vehicle's electric drive system

- Implementation of power supply system, battery swap, control and battery charging

- Design and implementation of customized fittings